RTLS Pallet Real-time Positioning and Tracking System

Innovative Smart Positioning Technology for Warehouse Management

The RTLS UWB Pallet Management System integrates Ultra-Wideband (UWB) high-precision positioning with RFID automatic identification, providing intelligent asset tracking for warehousing, logistics, and manufacturing industries.

The system operates through the collaborative work of ceiling-mounted base stations, forklift locators, and pallet RFID tags, precisely achieving real-time positioning and dynamic management of pallets and equipment, giving you comprehensive control over every aspect.

This solution offers high-accuracy location tracking, automatically records pallet loading and unloading movements, and seamlessly integrates with existing WMS or ERP systems.

Bid farewell to tedious manual inventory costs, significantly enhance warehouse operational efficiency, and achieve process automation and data transparency.

System Core Advantages

High-Precision Positioning

Utilizes UWB (Ultra-Wideband) technology to achieve positioning accuracy within 10 centimeters in ideal environments, ensuring the precision and reliability of asset location tracking.

Real-time Tracking Updates

The system provides high-frequency real-time location information, perfectly adapting to dynamic logistics and warehousing scenarios, allowing managers to monitor asset movements at all times.

RFID Automatic Identification

Integrates a 125K RFID reader to automatically read tags and instantly log the placement or removal of pallets, completing data recording without manual intervention.

Anti-interference, Stable

The system is optimized for industrial environments, maintaining excellent stability and reliability even in complex situations involving metal reflections, equipment electromagnetic noise, and other interferences.

Multi-Device Monitoring

Supports simultaneous tracking of multiple pallets and equipment, scalable for large-scale warehousing applications, meeting the system flexibility and expansion capabilities required for enterprise growth.

Applicable Industries and Application Scenarios

The RTLS UWB Pallet Management System is specifically designed for modern warehousing, manufacturing, and supply chain management needs, providing a comprehensive smart tracking solution. Whether it's pallet inventory in large logistics centers, material tracking on manufacturing floors, or efficiency optimization in supply chain hubs, this system delivers exceptional performance, helping enterprises achieve their digital transformation goals.

Warehousing and Logistics Management

- Real-time inventory of pallet locations and stock status

- Automated loading and unloading registration operations

- Seamless integration with WMS/ERP systems

- Reduce manual inventory time and error rates

Manufacturing Site Control

- Track the movement of work-in-progress and finished goods

- Integrate with production line systems to manage material flow

- Optimize material scheduling efficiency in the production process

- Enhance the visibility of on-site operations

Smart Supply Chain Operations

- Improve the collaborative efficiency of forklifts and material handling equipment

- Collect big data for operational analysis and optimization

- Shorten goods search and dispatch times

- Enhance supply chain transparency and traceability

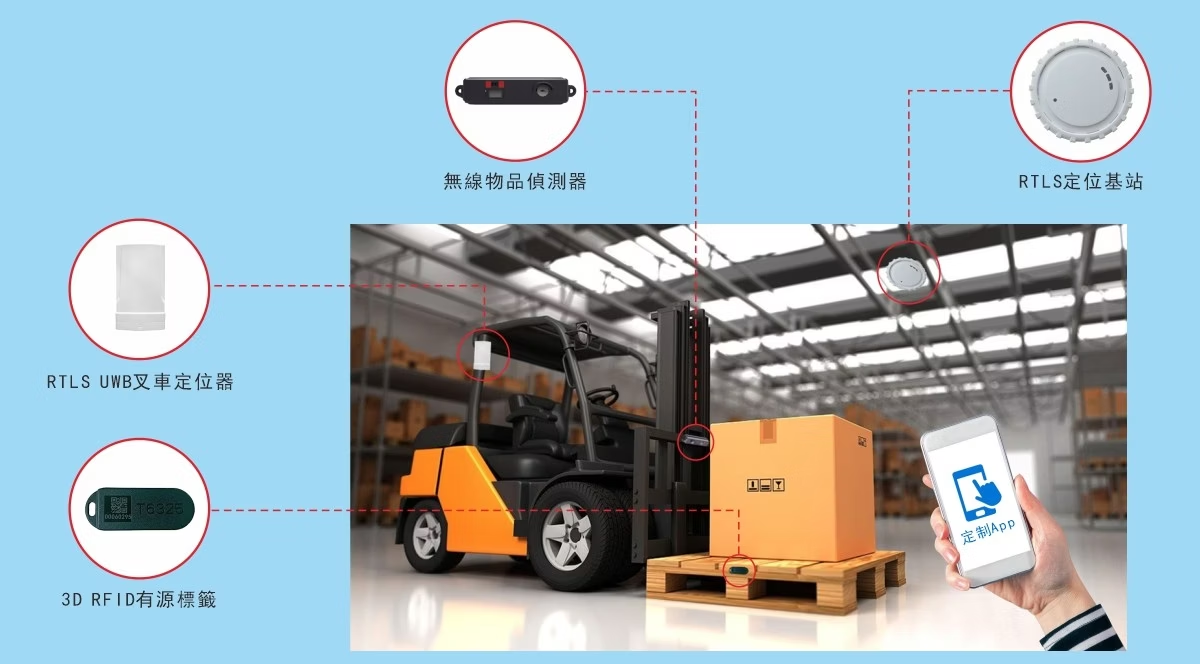

Solution One: RFID + UWB Forklift Pallet Tracking System

This innovative solution ingeniously combines active RFID tags with cutting-edge UWB positioning technology, aiming to provide you with unprecedented comprehensive pallet tracking and intelligent forklift management. This solution is particularly suitable for large-scale operational environments with a vast number of pallets and extensive areas, effectively improving management efficiency and accuracy. Through the perfect collaboration of key components—pallet tags, forklift locators, item detectors, and positioning base stations—we meticulously build a seamless and efficient intelligent positioning ecosystem to help your enterprise achieve operational excellence.

3D RFID Active Tags

Model: WS-ATAG6325-X

Installed on pallets, identifying pallet numbers and real-time status. Utilizes active design to ensure stable signals and support long-range reading.

RTLS UWB Forklift Locator

Model: WS-RTLS-125K

Installed on forklifts, tracking forklift positions and interactions with pallets. Integrates 125K RFID functionality for automatic pallet tag identification.

Wireless Item Detector

Model: WS-Hawkeye-C

Intelligently detects items or pallets on forklifts, automatically recording changes in cargo loading and unloading. Wireless design precisely determines forklift operational status.

RTLS Positioning Base Station

Model: WS-RTLS-PR

Installed in the warehouse to receive positioning signals and calculate precise locations. Supports PoE power supply, ensuring full-area positioning coverage.

Solution Two: UWB Positioning Tag System

This solution, centered on pure UWB positioning tag technology, offers a simplified deployment process. It is particularly suitable for managing valuable or high-value palletized items, providing more detailed tracking and security. Notably, in addition to general-purpose positioning tags, our innovative UWB positioning display tags can instantly present pallet contents and target locations, bringing unprecedented real-time visibility and decision support to your warehouse management, making it a key differentiating advantage for improving operational efficiency.

UWB Positioning Tag

Model: WS-UWB65L

Installed on pallets. Immediately begins precise positioning within the warehouse system.

UWB Positioning Display Tag

Model: WS-UWBPDT

Installed on pallets. Provides real-time insight into pallet contents and target locations, assisting with precise management and efficient decision-making.

.avif)

RTLS Positioning Base Station

Model: WS-RTLS-PR

Installed on warehouse ceilings, receiving signals from all UWB positioning tags. Calculates positions using algorithms, achieving precise, full-area tracking.

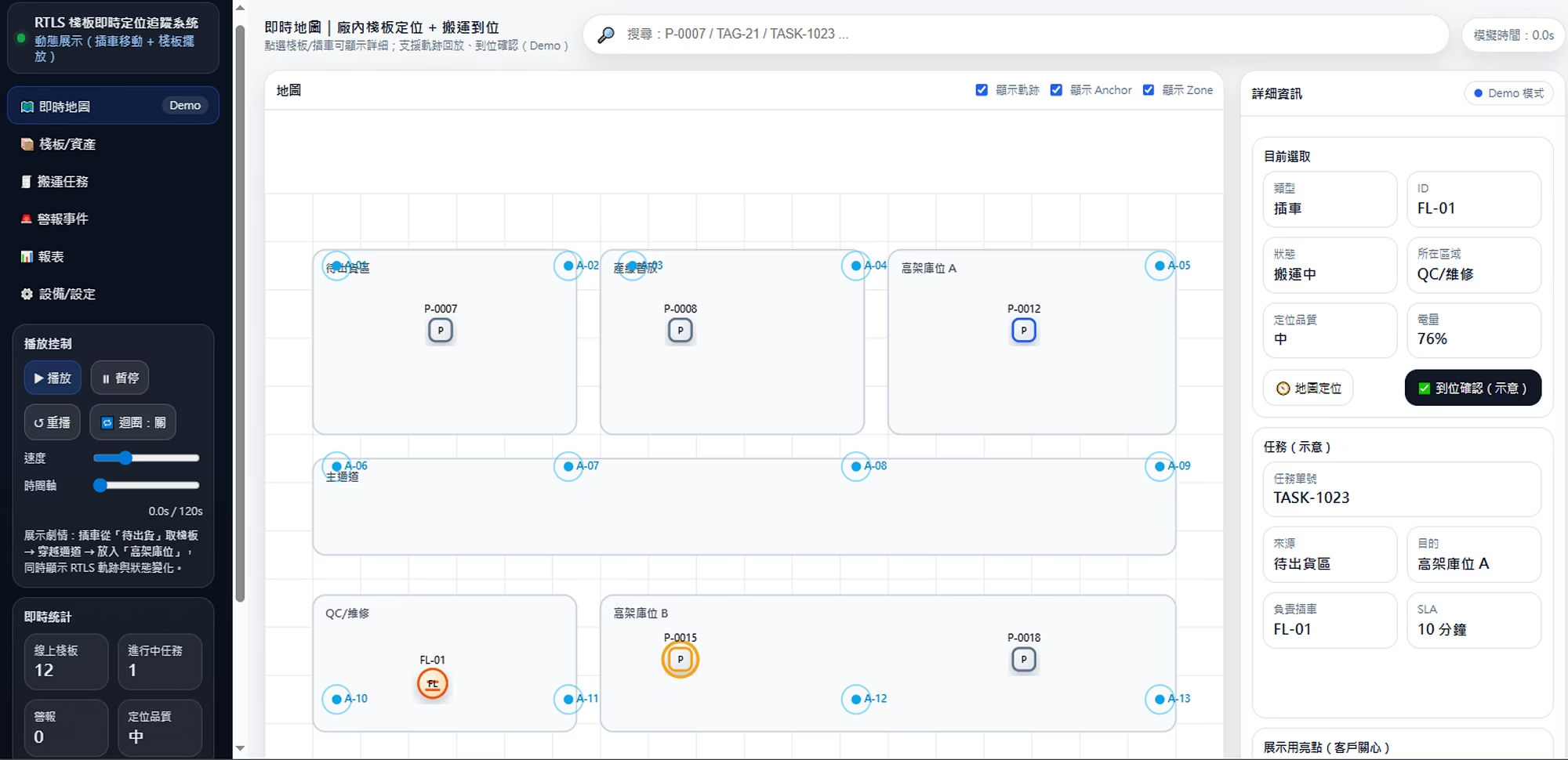

Pallet Real-time Location Tracking System Backend Display